|

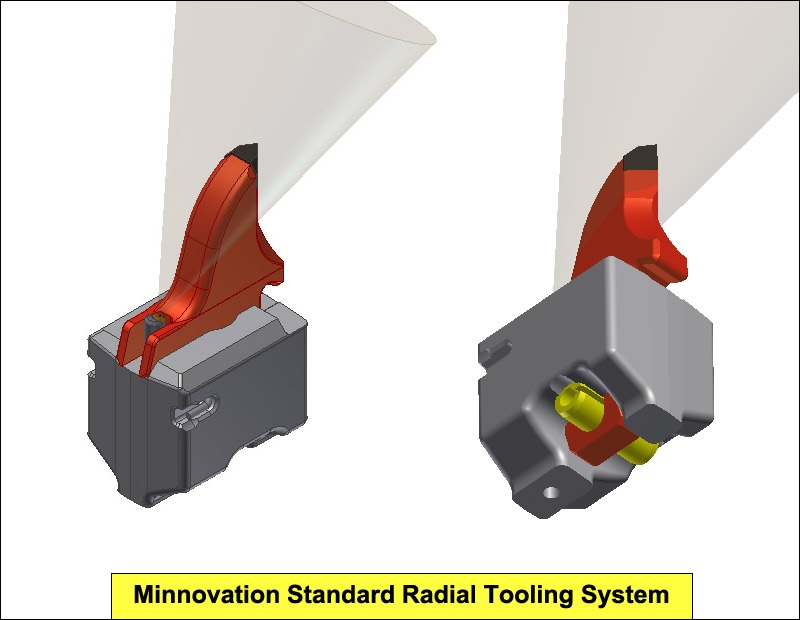

Minnovation have now designed & manufactured a standard radial block that accepts the current generation of "oblong shank” radial tooling produced by Kennametal, Hydra (ESCO), and Betek.

As part of this radial development radial sprays have been designed and manufactured by Minnovation to accommodate both 4”and 5” reach radial tools. ITP test & approval certificates have been supplied by Minnovation to Kennametal Australia and they are now successfully marketing their radial tools in combination with Minnovation radial sprays.

The Minnovation standard radial blocks that accepts the current oblong shank tooling is available to purchase.

|

Click spray images below for flow charts.

Radial Tooling System Improvements

The new Minnovation radial block should overcome the current radial tooling problems here listed below with improvements highlighted in red:

1. Block cracking during construction welding and in operation.

This problem will be significantly reduced as the Minnovation block will be 3 3/4” (95.25mm) wide. The current available block is 3 ¼” (82.5mm) wide.

2. Block wear due to loose retention of the radial tool allowing chatter.

As an alternative to the nylon gripper retainer, a new roll pin retainer can be offered which will hold the radial tool down more firmly in the block.

3. Radial Tool loss due to poor retention.

The problem will be reduced by adopting the roll pin retainer.

4. Spray damage due to radial tool loss.

This problem should be solved by not losing tools and exposing the spray.

5. Jammed radial tools due to the nylon gripper retainer being wider than the shank width and unable to move coal residue packed in the block.

The Roll Pin retainer can be knocked through the shank leaving no protrusions so extraction will be made much easier.

6. Spray blockage and unable to be cleaned as the nozzle is braised to the body.

The new radial spray has a removable nozzle allowing dis-assembly and cleaning and has already been proven a big benefit in Australian applications.